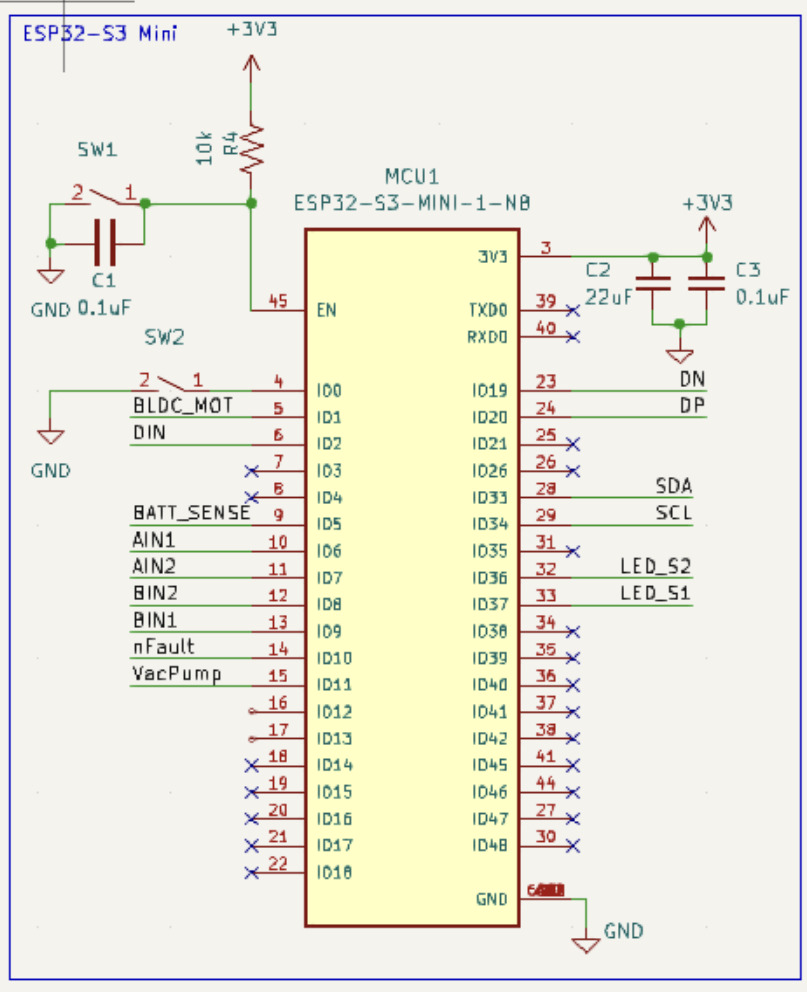

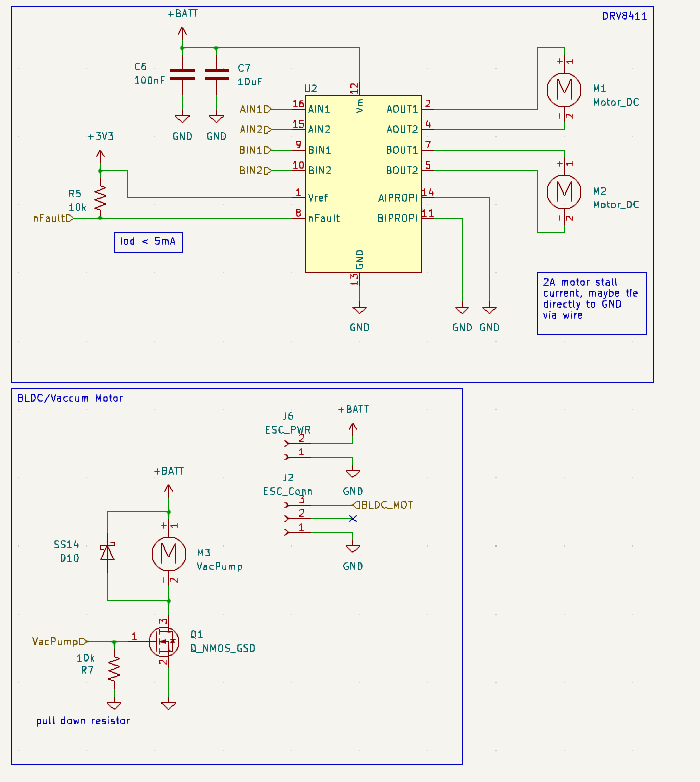

This PCB is designed to manage and control multiple components, providing versatile functionality. It supports two DC motors with forward, backward, and mixed mode capabilities, as well as a single DC motor for the vacuum mechanism.

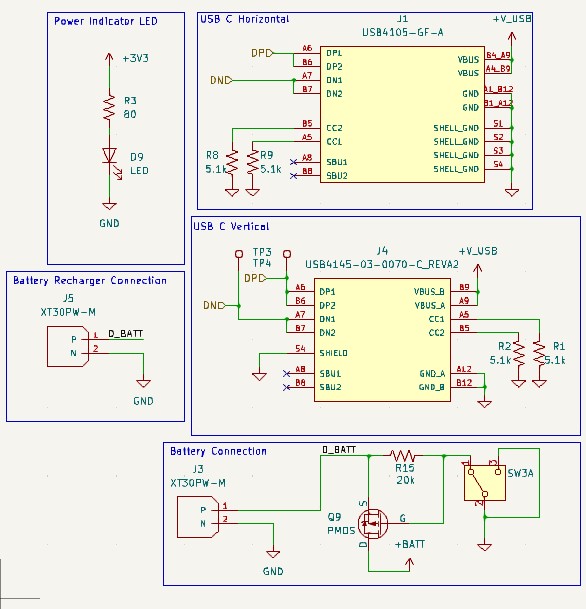

To enhance debugging and testing efficiency, I had some built-in mechanical features. Notably, there is a vertical USB-C mount.

This design choice addresses the challenge of accessing the robot's internals when it is enclosed in its case.

Typical horizontal mounts are difficult to reach in such scenarios, but the vertical USB-C mount allows for convenient access,

making uploading code and debugging much easier without the need to repeatedly unscrew and reassemble the robot's lid.

To enhance debugging and testing efficiency, I had some built-in mechanical features. Notably, there is a vertical USB-C mount.

This design choice addresses the challenge of accessing the robot's internals when it is enclosed in its case.

Typical horizontal mounts are difficult to reach in such scenarios, but the vertical USB-C mount allows for convenient access,

making uploading code and debugging much easier without the need to repeatedly unscrew and reassemble the robot's lid.

Additionally, I included an extra vertical XT30 connector for improved battery charging accessibility. While the horizontal XT30 connector is used for standard battery connections, charging the robot within its case traditionally requires the same tedious process as with USB-C: unscrewing the case, charging the battery, and screwing everything back together. To simplify this, the additional XT30 connector is externally accessible, just like the vertical USB-C, enabling hassle-free battery recharging.

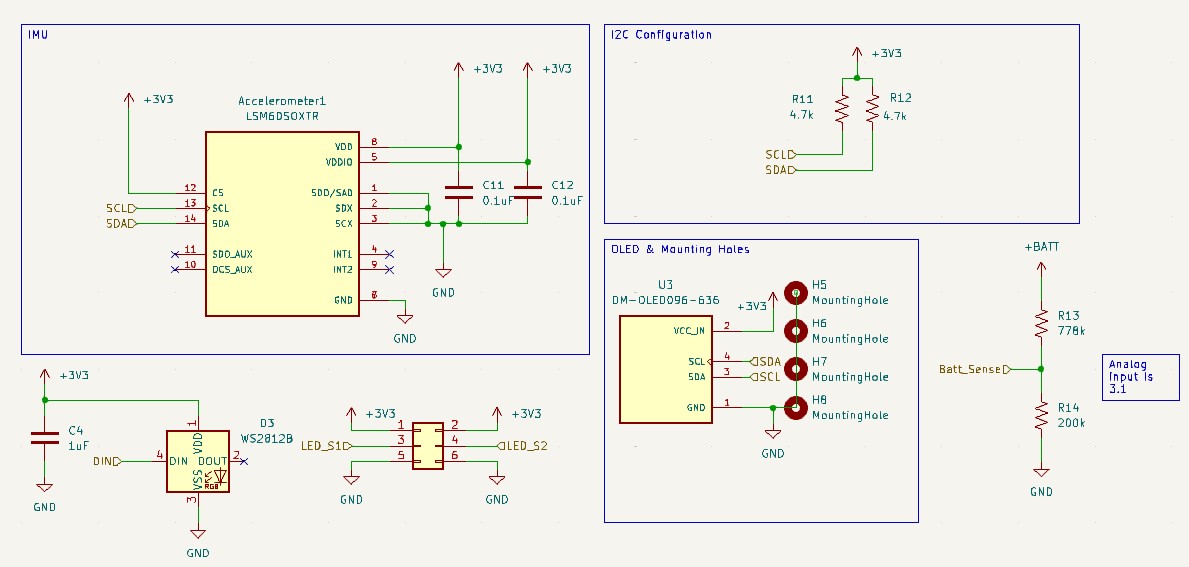

The design also features an onboard OLED display for live debugging indicators, along with LED strip ports for enhanced visual feedback.

The brushless ESC motor port serves a dual purpose: it can connect auxiliary motor fans to improve suction capabilities or be used to control a brushless ESC motor directly.

This brushless ESC capability is outside the scope of this project.

The design also features an onboard OLED display for live debugging indicators, along with LED strip ports for enhanced visual feedback.

The brushless ESC motor port serves a dual purpose: it can connect auxiliary motor fans to improve suction capabilities or be used to control a brushless ESC motor directly.

This brushless ESC capability is outside the scope of this project.